Shock Freezing

BMSERVICE specializes in providing efficient and innovative refrigeration solutions for various sectors of the food industry.

We offer a full range of shock freezing solutions:

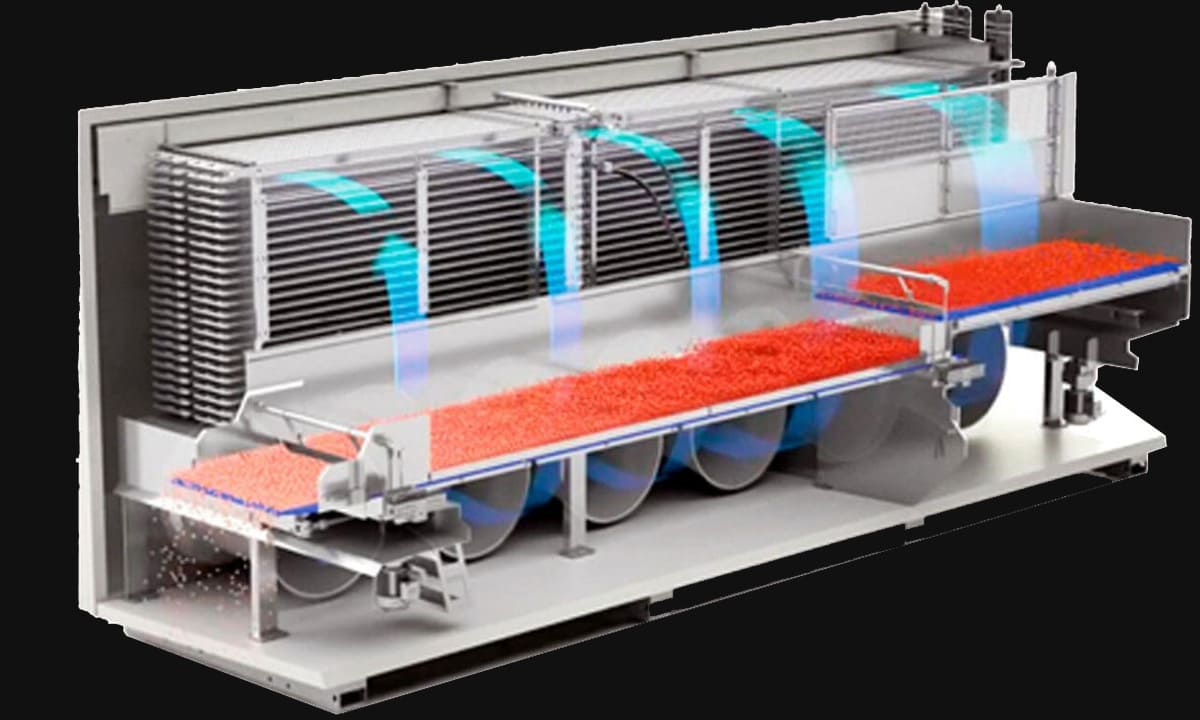

The fluidized tunnel freezer

The advantages are individualized freezing without parts sticking together, uniform processing on all sides, and high quality freezing.

Fluidized Quick Freeze Machine

This class of Fluidized Bed Freezer provides the highest freezing speed (among air machines), minimal loss of moisture, and maintains high product quality. After freezing, the product has its original crumbly structure and is perfectly packaged.

The purpose of fluidized freezer

They are typically used for freezing berries, herbs, meat, fish products and crushed vegetables and fruits.

Spiral freezers

Spiral shock freezers are widely used in the food industry for freezing and quick cooling of freshly prepared semi-finished products, meat, fish, vegetables, fruits and bakery products.

Composition of a spiral conveyor for blast freezing

Spiral multi-tier conveyor, heat-insulated chamber, low-temperature refrigeration unit and control panel.

The principle of operation of the spiral shoker

In a spiral blast freezer, the product continuously moves along a spiral conveyor in a chamber with ultra-low temperature and intense blowing.

Cold plate freezer

Cold plate freezers are designed for very fast freezing of large volumes of products in a short period of time.

This is achieved due to the design of the device and direct contact between product and freezing plates, which have an internal refrigerant circuit.

Modern cold plate freezer can work on various refrigerants, including CO2

Vertical plate freezers

It is a device in which products are loaded into its vertical blocks, where a refrigerant with an ultra-low temperature circulates.

Horizontal plate freezers

In the horizontal plate freezer, the products are placed in block molds and loaded manually between the plates. The plates are then compressed by a hydraulic system. After freezing, hot steam defrosting and a hydraulic lifting system are used to unload the blocks.

Shock freezing chambers

Shock freezing chambers are designed for very fast freezing, which allows you to maintain high product quality without damaging the texture of the product with ice crystals.

Shock freezing chambers are used for:

- shock freezing of food and semi-finished products (dumplings, pizza, cutlets, pancakes, cabbage rolls and similar products)

- intensive cooling and freezing of fish and fish products, shrimp, squid, poultry, meat and meat semi-finished products

- freezing bread and pastries, berries, mushrooms, vegetables, fruits

Intensive cooling chambers

Almost all industrial enterprises that work with large volumes of products use intensive cooling chambers. After all, their technological process requires rapid temperature reduction.

What is an intensive cooling chamber?

An intensive cooling chamber is a powerful cooling chamber that cools the product very quickly by intense blowing.

Where are intensive cooling chambers used?

- Cooling berries and fruit from the field, immediately after harvest, to maximize shelf life

- Cooling semi-finished products after partial cooking

- Cooling of dough and bakery products

Shock freezing for production

We offer installation and assembly services for Shock freezing and other refrigeration equipment. Our team has extensive experience and knowledge to guarantee professional and high-quality work.

We understand the importance of proper installation, as it affects the efficiency and duration of the equipment.

Cooperating with us, you can take advantage of professionally prepared projects that provide a number of benefits:

≫ qualified selection of the optimal technological solution;

≫ increasing food security;

≫ reduction of costs and losses of goods during storage;

≫ increasing the competitiveness of products;

≫ increase in profits;

≫ reduction of energy costs for storage and processing;

≫ reliability and durability of refrigeration equipment.

Shock freezing is the latest technology for preparing berries, fruits and vegetables for long-term storage while preserving their aroma, shape, taste, minerals and vitamins. This reflects the main feature of the method compared to others. Shock freezing of fruits, vegetables, and berries helps to preserve all the beneficial properties of frozen products. Compared to vegetables stored in a cellar or refrigerator, vegetables frozen with shock freezing have many times more benefits. In terms of profit, the line for shock freezing vegetables and fruits is a highly profitable business. In winter, the cost of such products on the market increases many times over. Using the blast freezing method, you can freeze products for future use in cooking, sell them to stores and retail chains all year round without losing profit.

Розгорнути

Freezing lines and blast freezing conveyors

Our company specializes in providing comprehensive refrigeration solutions. BMSERVICE has been designing and installing commercial and industrial refrigeration equipment for over 10 years.

Shock freezing line

We will design and implement your custom freezing line, taking into account all the technological processes of your enterprise. The blast freezing line is made with a spiral conveyor or a tunnel-type fluidization apparatus, depending on the needs of your enterprise. (The freezing line is an ideal solution for most processing, storage or storage enterprises)

Shock freezing conveyor

When ordering a blast freezing conveyor, you will receive a project tailored to all the needs of your enterprise, starting with refrigeration and freezing equipment, processing lines and sorting lines, refrigerated and freezing rooms and warehouses, heat recovery for the needs or technological processes of the enterprise, installation of remote monitoring of refrigeration equipment, and much more. Our company has extensive experience in the design and implementation of refrigeration projects of varying complexity, please contact us!

Shock freezing equipment

Shock freezing is a special technology that allows you to freeze almost any food product while preserving its flavor and nutritional properties.

Shock cooling and freezing equipment is used:

- Retail facilities – restaurants, large cafes, canteens, small shops

- Commercial refrigeration – confectionery factories, supermarkets, megamarts

- Production facilities – bakeries, fish and meat processing plants, juice factories, dairies, bakeries, and other food processing industries

- Industrial cold storage and warehouses – fruit and vegetable storages, distribution centers and other types of warehouses for long-term storage of products (for such enterprises, a blast freezing conveyor is most often designed)

What products require shock freezing:

- Shock freezing of berries – usually raspberries, strawberries, currants, cranberries, blueberries, cherries, etc

- Shock freezing of chopped fruits – apples, plums, oranges, pears and grapes and many other fruits

- Shock freezing of chopped vegetables – cucumbers, cabbage, carrots, beets, radishes, etc

- Shock freezing of herbs – parsley, dill, celery

- Shock freezing of meat products – meat, semi-finished meat products

- Shock freezing of fish products – fish, fish fillets, shrimps, and other seafood

- Shock freezing of bakery and other products – bread, cakes, confectionery, dumplings, dumplings, pancakes, etc

Shock freezing: the main features of the method

Shock freezing technology involves exposing fruits to ultra-low temperatures for a short period of time. Fruits and vegetables freeze completely and quickly under the influence of cold, which favorably affects their shape, color, appearance and quality. Almost all vitamins, minerals and other nutrients are preserved in the fruit. Thanks to the use of this quick freezing technology, crystals do not form in the fruit, which can have a destructive effect on the flesh.

For instant freezing and to prevent crystalline icing, the temperature must be between -5 and -18°C. It is in this temperature range that fruit is shock frozen. If the temperature is higher, the flesh will soften, and the fruit will lose its shape, appearance, and taste. If the temperature is too low, the food dries out. This is the difference between fast freezing, which prevents the formation of crystalline icing and freezing of moisture in the fruit.

Freezing line – features of fast freezing of berries and vegetables

In general, the stages of industrial quick freezing are divided into the following:

- Fruit preparation.

- Shock freezing.

- Storage.

To begin with, all the produce is sorted out, dirt is washed off, and unusable and deformed fruits are removed. Juice that can leak out during freezing will cause sticking. Next, the products are washed and dried, after which they are sent to the freezer. During the process of shock freezing of fruits, vegetables, berries, fruits are blown with frosty air from all sides, which ensures uniform freezing. The duration of cooling and freezing depends on the size of the fruit and the intensity of the air flow. Storage conditions for products after quick freezing are as follows:

- The temperature should be between -5 and -18°C.

- Do not allow defrosting.

- Careful consideration should be given to transportation and delivery from the place of blast freezing of vegetables, fruits and berries to the place of storage. This is to prevent frozen products from coming into contact with warm ambient temperatures.

Another important process in the entire chain of such fruit preservation technology is defrosting. Incorrect defrosting can have a negative impact and all the efforts that were made during the freezing process will be in vain. Vegetables and fruits should be thawed at a temperature between +2 and +4°C for 12 hours. Gradual defrosting allows you to preserve all the flavors.

Freezing line – the benefits of fast freezing of fruits and vegetables

The main advantages include the following:

- The structure of the frozen fruit remains intact and homogeneous.

- The range of fruits is expanded by the use of the shock freezing method. Even the most delicate fruits and berries can be frozen by rapid cooling.

- The method reduces labor costs for fruit processing.

- The ability to do business all year round, regardless of the season.

- Minimal amount of waste.

- Quick freezing equipment takes up little space and allows you to free up space for other devices.

- Fruits do not lose their shape, color, taste and flavor.

- Bacteria that could remain on the raw materials are completely killed by low temperatures.

The advent of shock freezing technology has made it possible to freeze almost all fruits. Vegetables are frozen in their natural state, without the use of preservatives and stabilizers.

Equipment for shock freezing of fruits, vegetables and berries from our company

On our website you can find the following models of equipment for the line of shock freezing of fruits, berries, vegetables, meat and fish products:

- Tunnel-type fluidization machines. This equipment prepares berries, vegetables, fruits, and mushrooms for storage. In the chambers, the products are frozen due to the influence of cold air under high pressure. The main advantage is that the products are frozen evenly from all sides and do not merge with each other. The method is suitable even for products that crumble easily.

- Equipment for deep freezing of vegetables, berries and fruits. This method freezes products at a temperature of at least -18 degrees. This allows you to preserve all the flavor of the fruit, as well as its structure. Vegetables and fruits do not lose their volume.

- Spiral conveyor for shock freezing. Spiral blast freezers are designed for fast freezing (6 – 90 minutes) of single and small packaged meat, fish products, fillets, packaged and unpackaged products, culinary semi-finished products and seafood.

- Plate freezers (vertical plate freezers and horizontal plate freezers). Tile machines are designed for contact freezing of blocks of minced meat, fish and fish fillets, seafood, meat, tenderloin, poultry, offal and semi-finished products, i.e. products that can be shaped into a regular rectangular shape.

- Shock freezing tunnel. The purpose of blast freezing tunnels is to shock freeze fruit and vegetable products, as well as meat, poultry, fish and other food products. Ready-to-eat food is frozen. Thanks to the high freezing speed, the product retains its full set of flavor and nutritional value. Weight loss is also minimal.

- Shock freezing chamber. The shock freezing chamber provides rapid cooling through forced ventilation of berries, fruits, vegetables, meat and fish products, ready meals, and semi-finished products in industrial volumes. In order for the natural properties of fruits and delicacies to fully preserve their nutritional and flavoring qualities, cooling to the state of deep freezing must be intense. The shock chamber is commonly used in small enterprises and retail facilities.

Our company is engaged in the creation of turnkey blast freezing equipment, whether it is a freezing line, freezing conveyor, processing, cooling and storage lines.

How to choose equipment for a blast freezing line

It is necessary to select shock equipment for enterprises depending on how large-scale the production is. This type of food freezing is used at all enterprises related to the food industry. This is a progressive technology that allows you to preserve not only the useful properties of berries, but also their presentable appearance. It is this type of freezing that has helped many companies to make their products better. Before purchasing a device for shock freezing fruits and vegetables, you should pay attention to the following criteria:

- type of loading – regular or tunnel;

- capacity;

- material of the chamber;

- ergonomic shape;

- internal volume;

- number of operating modes.

The cost of the equipment will depend on these parameters.

Business areas in which shock freezing lines for berries and fruits are used

This type of freezing process provides new opportunities for business. This method allows you to extend the shelf life of berries, fruits and vegetables. Mostly, shock freezing is in demand in such industries:

- Public catering establishments. Preparations can be served at any time of the year.

- Trade. This type of freezing allows you to sell fruits, vegetables, berries throughout the year.

- Catering. Frozen fruits can be transported to various events even in the off-season.

Freeze line from design to implementation

Since 2009, our company has been manufacturing refrigeration equipment on an industrial scale, as well as designing, implementing and maintaining conveyors and blast freezing lines. You can order a blast freezing line, spiral freezers, tunnel-type fluidization machines, tile freezers (vertical or horizontal), blast freezers, blast freezers, chillers, units and installations of the KKB, or order a turnkey project from us.

The price will depend on the type of equipment. To implement our projects, we use only proven components from American and European manufacturers. We provide a warranty for the equipment. If you can’t decide on the type of equipment for freezing products, you can call our consultant, and he will help you choose a device for quick freezing and place your order. Contact details are available on the website. Delivery is carried out on the territory of Ukraine.