Shock freezing of vegetables and fruits

Our company specializes in providing effective and innovative solutions for cooling and shock freezing of various fruits and vegetables.

We offer a full range of solutions for intensive cooling and shock freezing of vegetables and fruits:

Equipment for cooling and shock freezing of vegetables and fruits

Our company offers a full range of equipment for fast, intensive cooling and shock freezing of vegetables and fruits. We offer all types of shock freezing equipment on the environmentally friendly refrigerant CO₂. These systems provide significant energy savings, in some cases achieving a 25-40% reduction in energy consumption.

Intensive cooling chambers

The design of intensive cooling chambers is a heat-insulated chamber in which intensive cooling occurs with the help of high-intensity air flows, if necessary, the chamber can be equipped with a moisture control system that prevents drying fruits

Shock freeze cameras

Shock freezing chambers are designed for shock freezing of products on racks or trolleys, the chambers can be mounted in the form of a tunnel and have separate doors for loading and unloading products. The freezing process is carried out at a low temperature (up to -35 °С) for a very short time, usually from 15 to 90 minutes, the time depends on the product and its size. If necessary, the chamber can be equipped with a moisture control system to avoid drying of vegetables and fruits.

Spiral freezers

Spiral shock freezing lines are a compact conveyor that is designed in the form of a spiral, this solution makes the spiral shock freezing line an ideal solution for most vegetable and fruit processing enterprises. < span style="font-weight: 400;">Spiral Shock Freeze Conveyor can be installed at any stage of your processing line.

AEF acoustic freeze

The principle of the acoustic freezing chamber is a combination of two processes, intensive blowing with cold air, and the impact of sound waves on the product, this happens throughout the entire freezing process. Sound waves are selected in the device settings, separately for different types of products. The sound wave affects the ice microcrystals that begin to form in the product during freezing, this wave seems to break the crystal, preventing it from expanding and destroying the tissues of vegetables and fruits. Acoustic freezing technology can be used both in shock freezing chambers and in quick freezing tile (plate) devices. This innovative technology can be equipped in a shock freezing chamber, spiral conveyor, or in the fluidization apparatus of shock freezing.

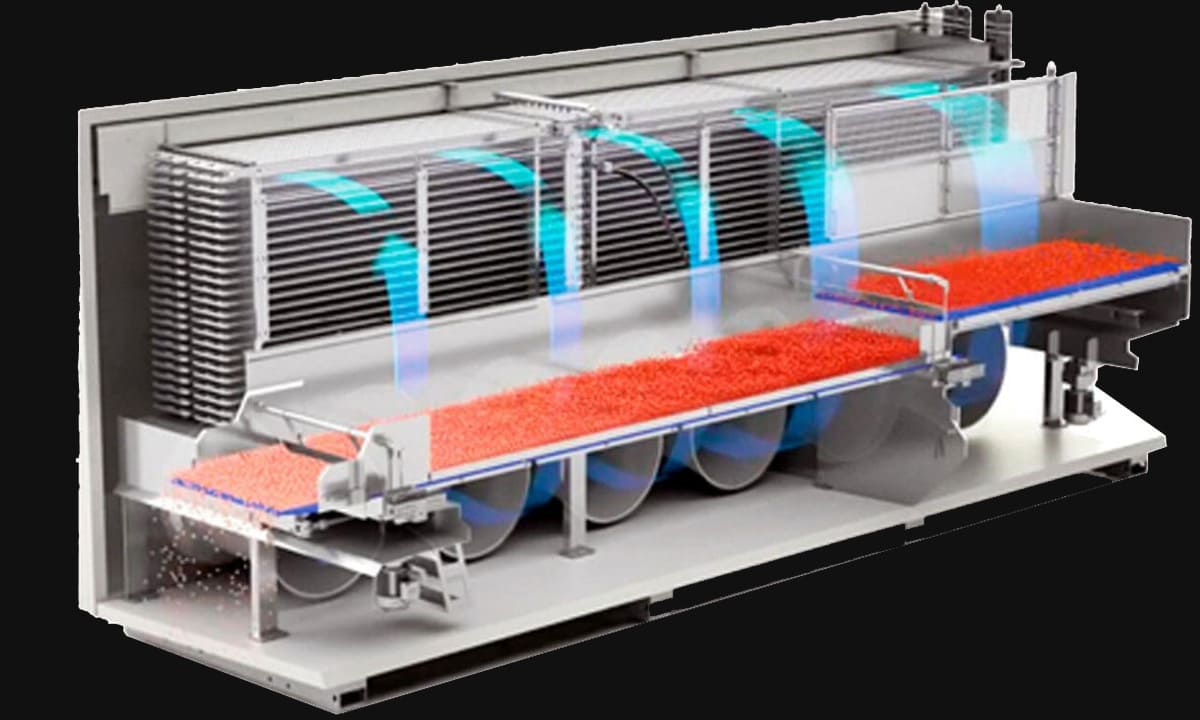

Tunnel-type fluidization machines

Fluidization conveyors are used for freezing loose, small and crushed products, portions of which should be frozen separately from each other to avoid sticking together. As an example, this type of shock freezing is ideal for freezing peas, potato chips, berries, etc. Products are frozen in an upward flow of cold air supplied through a perforated belt. The speed of the air flow is such that the products end up in a suspended state, which prevents them from sticking together.

We offer a full range of solutions for processing and storing vegetables and fruits: