The fluidized tunnel freezer

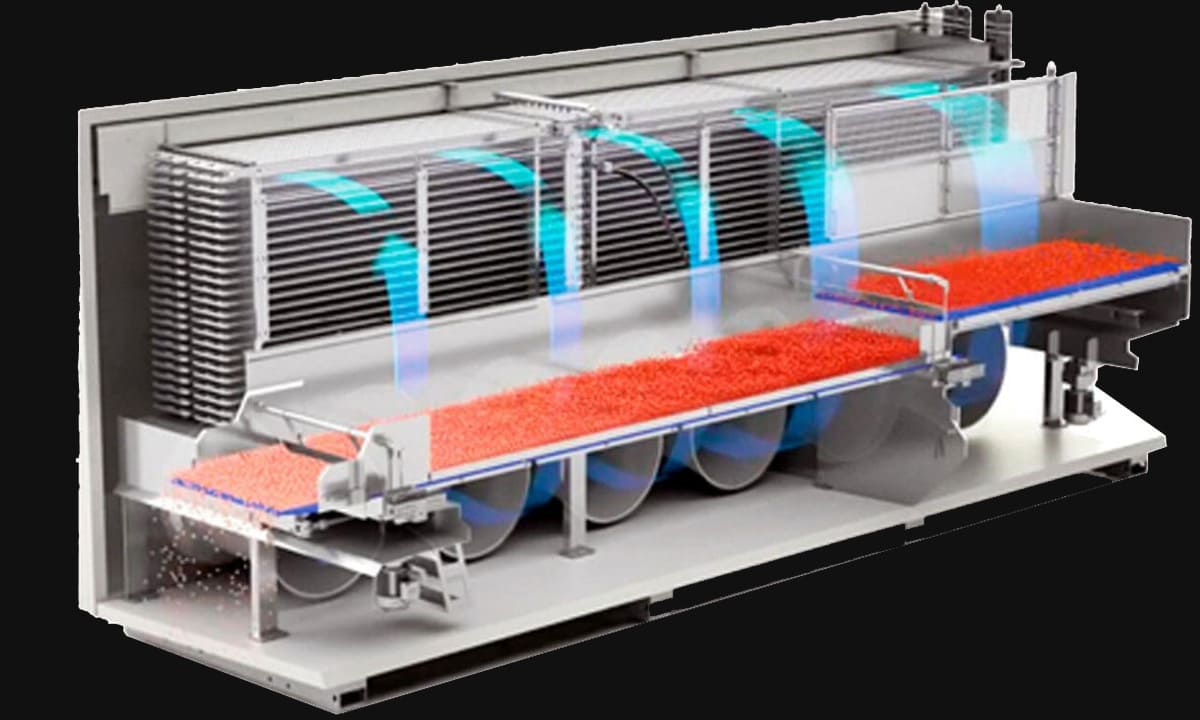

The fluidized tunnel freezer is a high-tech installation for fast and efficient freezing of various types of products. Fluidized Quick Freeze Machine uses vibration and air pressure to help separate products without sticking to each other.

The fluidized tunnel freezer uses a vertical airflow freezing method that ensures an even distribution of the airflow. Resulting in we have a more even crust and freezing.

Process principle of the fluidized tunnel freezer

The product is loaded onto the belt conveyor and moves to the freezing zone, where high-speed axial fans blow air through the evaporator and through the product itself.

At the exit of the tunnel section, the frozen product is smoothly separated from the conveyor belt. All items of the product are separated from each other.

The fluidized tunnel freezer is effective for freezing seafood, shellfish, shrimp, vegetables, fruits and berries.

Quick-freezing fluidization devices have 3 types

There are 3 types of fluidized tunnel freezers:

- Circulation fluidization, fixed bed fluidization. Circulation fluidization is used to completely lift the product from the bed under strong streams of cold air. It is usually used in the first part of the freezer to freeze the crust when the product is still warm and moist.

- Bubble fluidization is a gentler version of the previous type, and it only partially lifts the product (hence the name semi-fluidized layer) . It is usually used in the second layer, the already frozen product acts as a boiling liquid.

- Fixed bed fluidization is used for final freezing of the product in the last part of the tunnel, the product is mostly on the bed. It is also suitable for very fragile products. Of course, there can be variations of these 3 types.

The fluidized tunnel freezer

BMSERVICE specializes in providing efficient and innovative refrigeration solutions for various sectors of the food industry.

We offer a full range of shock freezing solutions: